Technical Information by Application

PVC Applications

- Suspension Polymerization of VCMs and Role of PVOH

-

Water-soluble polymers are often used as dispersing stabilizers for the suspension polymerization of vinyl chloride monomer (VCM). In particular, PVOH is a suitable agent optimizing the surface-active performance of VCM by selecting appropriate degree of polymerization and saponification value.

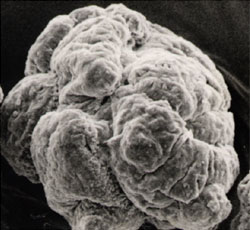

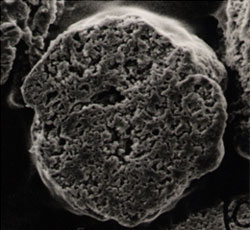

The suspension polymerization of VCMs is a technique used to produce PVC with a particle size of 50 to 200 μm. A VCM is suspended in water by means of stirring and use of a dispersing agent, and then polymerized for several hours to achieve PVC. The properties of the resultant PVC powder, including the size and shape of particles and bulk density, vary depending on the particle forming process during the polymerization.

In the particle forming process, the role of PVOH, which governs the properties of PVC powder, is very critical, where 50% to 80% of the properties of PVC powder depend on the surface activity performance of PVOH.

Furthermore, required properties of a dispersing agent constantly change. For instance, the speed of polymerization has been accelerated because of improved heat removal efficiency during the suspension polymerization process. Therefore, the need is mounting for a PVOH capable of satisfying requirements in both productivity and environmental protection, without limiting performance, for example, residual VCM removal.

To respond to a wide range of requests from the market, Nippon Gohsei offers a full line of proprietary dispersants for suspension polymerization of VCMs (i.e., primary and secondary dispersants) that have a variety of surface-active properties.

| Grade | Saponification Value (mol%) |

Viscosity *1 (mPa・s) |

Properties |

|---|---|---|---|

| GH-23 | 86.5 - 89.0 | 48 - 56 | For high BD |

| GH-22 | 86.5 - 89.0 | 45 - 52 | |

| GH-20 | 86.5 - 89.0 | 40 - 46 | |

| GH-17R | 86.5 - 89.0 | 27 - 33 | |

| KH-20 | 78.5 - 81.5 | 44 - 52 | Good polymerization stability |

| KH-17 | 78.5 - 81.5 | 32 - 38 | |

| KP-08R | 71.0 - 75.0 | 6.0 - 8.0 | Good porosity |

*1 : 4% aq. Solution at 20℃

| Grade | Saponification Value (mol%) |

Viscosity *1 (mPa・s) |

Product form | Properties |

|---|---|---|---|---|

| LW-100 | 39.0-46.0 | 500-2,500 | 39 - 41% aqueous solution |

Dispersing auxiliary for suspension polymerization of vinyl

chloride Adhesives Binder Anchor coating agent |

| LW-200 | 46.0-53.0 | 500-2,000 |

*1 : Viscisity measured by 39-41% aqueous solution at 25℃