Specialty Grades

Reactive PVOH Z Series

GOHSENX™ Z Series

Z Series is a specially modified PVOH containing a reactive acetacetyl group in its molecule.

Structural formula

- Properties

-

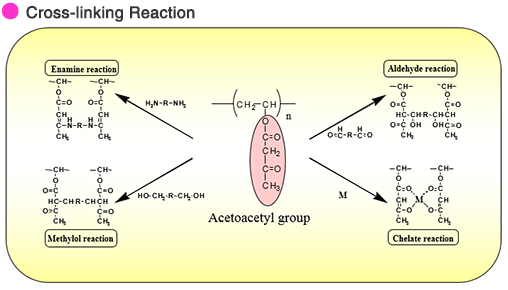

- ・Cross-linked by various methods

- - Adding a cross-linking agent

- - Self cross-linking by thermal treatment

- - UV cross-linking (in a hydrous or aqueous solution state)

- ・Functions as a protective colloid and a surfactant

- ・Adheres well to polarized surfaces

- ・Enables to form chelate

- ・Easy to unchain cross-linking by alkaline

-

| Product Grade | Saponification Value (mol % ) |

Viscosity *1 (mPa・s) |

pH *2 | Volatile Matter ( % ) |

Applications |

|---|---|---|---|---|---|

|

Z-100

|

Min.98.5

|

4.5 - 6.0

|

3.5 - 5.0

|

Max.5.0

|

Thermal recording paper

|

|

Z-200

|

Min.99.0

|

11.5 - 14.0

|

3.5 - 5.0

|

Max.5.0

|

Thermal recording paper, Adhesive

|

|

Z-205

|

Min.99.0

|

11.5 - 14.0

|

3.5 - 5.0

|

Max.5.0

|

Thermal recording paper

|

|

Z-210

|

95.0 - 97.0

|

11.5 - 15.0

|

4.0 - 5.3

|

Max.5.0

|

Emulsifier for vinyl acetate Em

|

|

Z-220

|

90.5 - 92.5

|

11.5 - 15.0

|

3.5 - 5.5

|

Max.5.0

|

Emulsifier for vinyl acetate Em

|

|

Z-300

|

98.0 - 99.0

|

24.0 - 30.0

|

3.5 - 5.0

|

Max.5.0

|

Adhesive

|

|

Z-320

|

92.0 - 94.0

|

19.0 - 24.0

|

3.5 - 5.0

|

Max.5.0

|

Water based vinyl urethane

|

|

Z-410

|

97.5 - 98.5

|

43.5 - 58.5

|

3.5 - 5.5

|

Max.5.0

|

Adhesive

|

*1. 4% aqueous solution at 20℃

*2. 4% aqueous solution at 30℃

Applications of GOHSENX™

- Emulsifier

- Water resistant bonding strength EM will be produced by using Gohsenx™ Z as emulsifier for vinyl acetate EM compared with conventional PVOH.

- Coating Agent

- Gohsenx™ Z is applied as coating agent for thermal printing paper, ink jet printing paper and so on, as increasing demand for coated and non-coated paper which require water resistant strength.

- Adhesive and Binder

- Gohsenx™ Z can use as adhesive and binder since excellent adhere and water resistance.

Recommended crosslinker(Sefelink™ SPM-01)

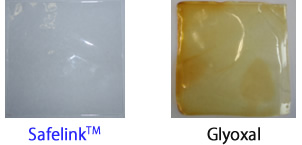

Safelink ™ SPM-01 is a new crosslinking agent for Gohsenx™ Z developed by our own technique. Both type of powdered and 10% aqueous solution are available.

- Characteristics

-

- ・Excellent crosslinkability for Gohsenx ™ Z.

- ・High safety with less toxicity compared to other crosslinking agents

- ・Easy handling with longer pot life after mixed with Gohsenx Z.

- ・Excellent color stability against heat and aging conditions.

| Cross-linking Agent | |||||

|---|---|---|---|---|---|

| Amount (parts) |

pH | Elution rate(%) ※1 |

Pot life ※2 |

YI ※3 |

|

| Safelink™ SPM-01 | 5 | 5.0 | 3 | More than 7days |

4 |

| Glyoxal | 1 | 4.4 | 6 | 7days | 12 |

※1. Dry film (heat treated for 5 min at 70℃) after soaking in 80℃ water for 1 hr.

※2. Period of reaching viscosity of 7% aqueous solution to twice at 23℃.

※3. After 100μm film left for 7 days at 40℃, 90%RH. (NIPPON DENSHOKU ∑90)

| Crsslinking agent | Product name | Chemical name | Product company | Add- intion *1 |

pH | Elution rate (%) *2 |

Pot Life (hr) *3 |

|---|---|---|---|---|---|---|---|

| Amine | MXDA | Methaxylenediamin | MITSUBISHI GAS CHEMICAL COMPANY, INC. | 3 | 10.5 | 20 | 0.1 |

| 1, 3-BAC | 1,3-bis (aminomethyl) cyclohexane |

3 | 10.5 | 20 | 0.1 | ||

| Hydrazide | ADH | Adipoyldihydrazide | Otsuka Chemical Co., Ltd. | 3 | 5.4 | 1001) | 0.1 |

| APA-280 | 3 | 5.4 | 15 | 0.1 | |||

| Aldehyde | SEQUAREZ 755 | Polyol Carbonyl Adduct |

OMNOVA Solutions Inc. | 3 | 4.3 | 10 | 9 |

| Metal Salt | ZIRCOZOL ZC-2 | ZrO(OH)Cl·nH2O | DAIICHI KIGENSO KAGAKU KOGYO CO., LTD. | 3 | 1.9 | 3 | Min.168 |

| ZIRCOZOL AC-7 | (NH4)2ZrO(CO3)2 | 3 | 4.8 | 202) | Min.168 |

*1 : Additive volume(Parts) / Z-200

*2 : After soaking dry film pretreated 70℃ × 5min in 80℃ water for 1hr

*3 : Measure period until 10% aqueous solution viscosity would be twice than initial viscosity as

40℃

1) : insoluble in cold water

2) : Elution rate at 90℃

| Emulsion NO. | 1 | 2 | 3 | 4 | |

|---|---|---|---|---|---|

| Polymerization Recipe | Z-210 (parts) | 4 | - | - | - |

| Z-220 (parts) | - | 3 | - | - | |

| N-300 (parts) | - | - | 5 | - | |

| GM-14 (parts) | - | - | - | 3 | |

| Vinyl acetate (parts) | 36 | 37 | 45 | 47 | |

| Water (parts) | 60 | 60 | 50 | 50 | |

| Polymerization Iinitiator | APS | APS | HPO/TA | APS | |

| Properties | Evaporation Residue (%) |

40 | 40 | 50 | 50 |

|

Viscosity |

15,600 | 27,300 | 13,000 | 53,000 | |

| pH | 4.3 | 4.2 | 4.5 | 4 | |

| Apparent Graft Ratio (%) |

76.1 | 76.1 | - | 42.3 | |

| Freeze-thaw Stability (number of cycles) |

5< | 5< | 0 | 5< | |

| Water-proof Adhesion Test |

13hrs | 95hrs | × | × |

NOTE

(1)APS:Ammonium peroxosulfate

(2)Apparent graft ratio: An emulsion film was air-dried at 20℃, treated with acetone at 40℃ for 8 hrs

and with hot water at 80℃ for 8 hrs, and the extraction-residue was calculated.

(3)In the water proof adhesion test, 100g/m2 of emulsion was applied to each face of birch

specimens. The specimens were then glued together and pressed for 24 hrs at 200 gf/cm². After

depressurizing, the resultant sample was left to stand for 24 hrs. This sample was used as a test piece.

The test piece was immersed in boiling water and the time needed for the bonded faces to come apart was

measured.

| Mixing Ratio | Emulsion Properties | G.f (%) |

|||

|---|---|---|---|---|---|

| Viscosity (mPa・s) |

S.V.I | Solids (%) |

|||

| Z-200 : 4 parts |

Initiator(APS) : 0.08 parts |

12,000 | 0.5 | 40 | 73 |

| VAC : 36 parts |

Buffer(NaOAc) : 0.02 parts |

||||

| Pure water : 60 parts |

|||||

| Z-100 : 45 parts |

Initiator(APS) : 0.08 parts |

2,300 | 0.3 | 50 | 69 |

| VAc : 45 parts |

Buffer(NaOAc) :0.02 parts |

||||

| Pure water : 50 parts |

|||||

Viscosity: Brook field viscometer, 10 rpm, 25℃

S.V.I: Obtained by log (viscosity at 2.5 rpm/viscosity at 20 rpm) ÷ 0.903

Solids: Obtained by drying samples for 3 hrs. at 105℃

G.f(%): Grafting ratio

An emulsion film was air-dried at 20℃, Treated with acetone at 40℃ for

8hrs and with hot water at 80℃ for 8hrs,

and the extraction-residue was calculated.

cf) G.f of GM-14 use Em. (55% solids) is 40-50%.

Dissolution and Storage

- Dissolving GOHSENX™ Z

- Put GOHSENX™ Z into room temperature water while stirring the water. Heat the water immediately while constantly and continuously stirring the water, and keep it at 90℃ to 95℃ for 30 to 60 minutes until complete dissolution.

- Storing GOHSENX™ Z

- The properties of a GOHSENX™ Z aqueous solution may change (e.g. its viscosity may increase) if stored for a long period of time. Color changes or viscosity increase may also be induced by rust or metallic ions entering the solution.

- Note

-

- ・When mixing GOHSENX™ Z with defoaming agents, anticorrosives, antiseptics, or other chemicals, follow the handling instructions of these chemicals.

- ・Avoid storage in a hot, humid area as the product may incur blocking or its properties may change.

- ・GOHSENX ™ Z is stable when stored at moderate temperature; however, GOHSENX ™Z has a functional group that makes the product chemically quite reactive, and contamination of other chemicals may cause the product to become insoluble or form gel.

| Polymer | COD (mg/kg) ×104 | BOD5 (mg/kg) ×102 |

|---|---|---|

| GOHSENX™ Z | 99 | 70 |

| GOHSENOL™ | 60 - 100 | 50 - 100 |

| Corn Starch | 36 | 7,400 |

Measuring conditions: Sample conc. mean pure material conc.

COD was measured by potassium permanganate method (JIS K 0102), and BOD5 is a 5-day BOD value.

Measurement: Registration No. of measurement certification enterprise, Osaka No. 10013, KK Osaka

Environmental Technology Center.